VFFS Machines & Bagging Machines

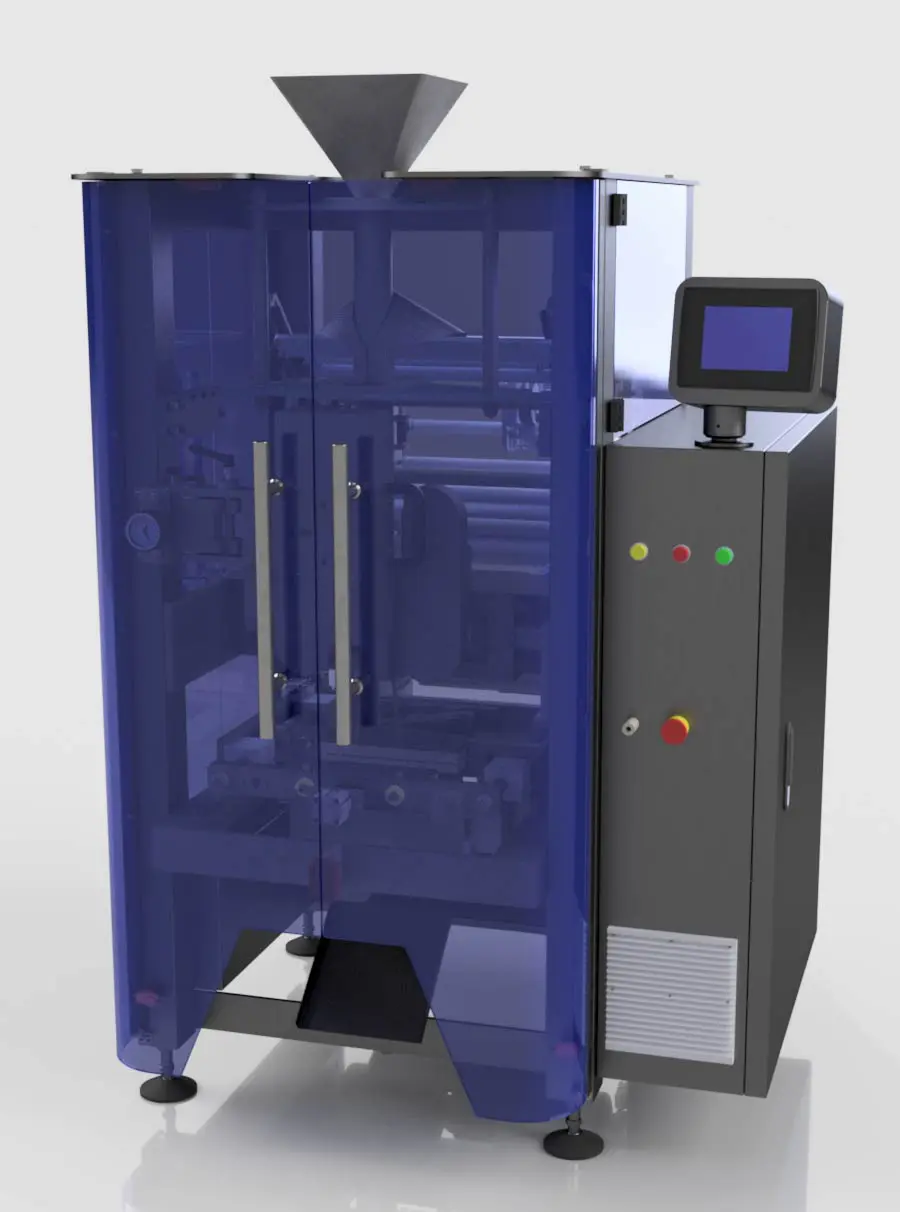

BESSEN Vertical Form Fill and Seal Machines: Versatile Solutions for Diverse Bag Styles and High-Speed Production Needs.Bessen Vertical Form Fill and Seal (VFFS) Machines: Designed for Efficiency and Versatility. With high readability, user-friendly operation, pinpoint accuracy, and exceptional packaging speeds, Bessen VFFS machines are the go-to solutions for diverse packaging requirements.

Our machines expertly handle both laminated and single-layer polyethylene film structures, working seamlessly with various bag styles including pillow bags, gusset bags, 4-way seal bags, and flat bottom bags. Additional customization options are available, such as hole punching, tear notches, end-seal cooling, bag vibration, film tracking, vacuum film assist, bag support, MAP flushing, air expellers, and bag inflators.

Bessen’s VFFS equipment can be integrated with a wide array of filling systems, encompassing combination scales, linear scales, vibratory feeders, indexing conveyor systems, auger fillers, piston fillers, and cup fillers. Discover Bessen’s commitment to providing complete, efficient, and customizable packaging solutions tailored to your specific needs.

V1000 Series Vertical Form Fill and Seal (VFFS) Machines: Precision Packaging Solutions for Diverse Bag Styles

BESSEN V1000 Series Vertical Form Fill & Seal (VFFS) Machines: Your Solution for Versatile Bagging Options & Efficiency

Bessen Vertical Form Fill & Seal (VFFS) Baggers: Versatility in Bagging Solutions. Our 1000 Series machines offer a wide variety of bag types, sizes, shapes, and styles, equipped with innovative functions and customizable options to meet your specific needs.

Ease of Use: Bessen VFFS machines feature an intuitive interface that empowers operators to quickly change programs, save and load preset parameters, and seamlessly switch between various bag styles and products. With up to 30 preset programs available, you can enjoy faster change-over times, maximizing efficiency.

Quality Assurance: Our state-of-the-art plastic tracing technology ensures precise plastic movement control, resulting in high-quality seals on the center seal. Trust Bessen’s VFFS machines for dependable, versatile, and easy-to-use packaging solutions, tailored to your industry requirements.

Optimal Fetchers

- Gusset device

- Hanging hall punching device

- Gas flashing

- Air removal

- Air expelling

- PE film sealing

- Seal cooling

- Vibrating

- Easy tear

- Bag support

Application

- Vegetables

- Frozen pasta

- Frozen vegetables

- Fresh pasta

- Dry product

- Powder product

- Liquid product

- Creamy liquids

- Chemical products

Filling application:

- Combination weigher

- Linear weigher

- Cup measuring device

- Auger filler

- Liquide filler (pneumatic)(servo)

Film Width – 5.5” to 28”

Bag Size – L * W (2.25” ~ 20”) * (2.5” ~ 13.75”)

Max Speed – 100 Bags/min (depending on bag size)

Power – 208~240V 1phase 60Hz 5.5KW

HMI – 7” or 9.7″ HMI Touch Screen

Drive System – 1 or 2 Servo Motors

Gross Weight – 1400LB

V2000 Series Vertical Form Fill and Seal (VFFS) Machines: Advanced, Versatile Bagging Solutions for Various Packaging Needs

BESSEN V2000 Series Vertical Form Fill & Seal Machines: Innovative Packaging Solutions for Diverse Bag Types & Sizes

Discover Versatility with Bessen’s Vertical Form Fill & Seal (VFFS) Bagger: Our 2000 Series machines are tailored for diverse bagging solutions, accommodating various types, sizes, shapes, and styles of bags. With multiple functions and options available, these machines offer unmatched customization.

Ease of Operation: Bessen’s VFFS machines boast an intuitive interface that simplifies the user experience. Operators can effortlessly make changes to the program, save, and load preset parameters, allowing quick transitions between different bag styles and products. With the ability to store up to 30 preset programs, we enable a faster change-over time, enhancing your production efficiency.

Quality Control: Leveraging advanced plastic tracing technology, we provide precise control over plastic movement, resulting in consistently high-quality center seal performance. Trust in Bessen’s commitment to excellence and innovation in packaging solutions with our Vertical Form Fill & Seal machines.

Optimal Fetchers

- Gusset device

- Hanging hall punching device

- Gas flashing

- Air removal

- Air expelling

- PE film sealing

- Seal cooling

- Vibrating

- Easy tear

- Bag support

Application

- Vegetables

- Frozen pasta

- Frozen vegetables

- Fresh pasta

- Dry product

- Powder product

- Liquid product

- Creamy liquids

- Chemical products

Filling application:

- Combination weigher

- Linear weigher

- Cup measuring device

- Auger filler

- Liquide filler (pneumatic)(servo)

Film Width – 6” to 20.5”

Bag Size – L * W (2.25” ~ 13.75”) * (3” ~ 10”)

Max Speed – 70 Bags/min

Power – 208~240V 1phase 60Hz 3.5KW

HMI – 7” or 9.7″ HMI Touch Screen

Drive System – 1 or 2 Servo Motors

Gross Weight – 1100LB

V3000 Series Vertical Form Fill and Seal (VFFS) Machines: Innovative Bagging Solutions for Multiple Sizes and Styles

ESSEN V3000 Series Vertical Form Fill & Seal (VFFS) Machines: Cutting-Edge Technology for Flexible and Efficient Bagging Solutions

Bessen 3000 Series Vertical Form Fill & Seal (VFFS) Baggers: Comprehensive Solutions for Varied Packaging Requirements. These machines are designed to accommodate a wide array of bag types, sizes, shapes, and styles, offering unmatched versatility and customization.

Intuitive Operation: Equipped with a user-friendly interface, Bessen’s 3000 Series allows operators to effortlessly make program adjustments, save and load preset parameters, and switch between different bag styles and products. With the capacity to store up to 30 preset programs, these machines enable faster change-over times, boosting your productivity.

Quality Assurance: Our innovative plastic tracing technology provides precise control over plastic movement, ensuring superior quality seals on the center seal. Choose Bessen’s 3000 Series VFFS machines for reliable, efficient, and versatile bagging solutions tailored to your specific needs.

Optimal Fetchers

- Gusset device

- Hanging hall punching device

- Gas flashing

- Air removal

- Air expelling

- PE film sealing

- Seal cooling

- Vibrating

- Easy tear

- Bag support

Application

- Vegetables

- Frozen pasta

- Frozen vegetables

- Fresh pasta

- Dry product

- Powder product

- Liquid product

- Creamy liquids

- Chemical products

Filling application:

- Combination weigher

- Linear weigher

- Cup measuring device

- Auger filler

- Liquide filler (pneumatic)(servo)

Film Width – 6” to 20.5”

Bag Size – L * W (2.25” ~ 13.75”) * (3” ~ 10”)

Max Speed – 70 Bags/min

Power – 208~240V 1phase 60Hz 3.5KW

HMI – 7” or 9.7″ HMI Touch Screen

Drive System – 1 or 2 Servo Motors

Gross Weight – 1100LB

MON – FRI

08:30am – 6:00pm

Emergency calls

&

Contract Costumers

SUN

By appointmenr

Drop Us a Line

Don’t be shy. Let us know if you have any questions!