WELCOME TO BESSEN

Leading Manufacturers of Automated Packaging Solutions: Conveying, Weighing, Filling, Bagging, Wrapping, Metal Detecting & Complete Food Processing Systems. Explore Our Innovative and Efficient Equipment for All Your Packaging Needs at BESSEN.Our Story

Welcome to Bessen Corp

BESSEN: Your Trusted Manufacturers of Automated Packaging Equipment. Specializing in Spiral Freezers, Chillers, Conveyors, Weighing Systems, Filling Machines, Bagging & Wrapping Systems, Metal Detectors, and Complete Food Processing & Packaging Systems. Experience Efficiency, Quality, and Innovation with BESSEN's Tailored Solutions for Your Industry Needs.

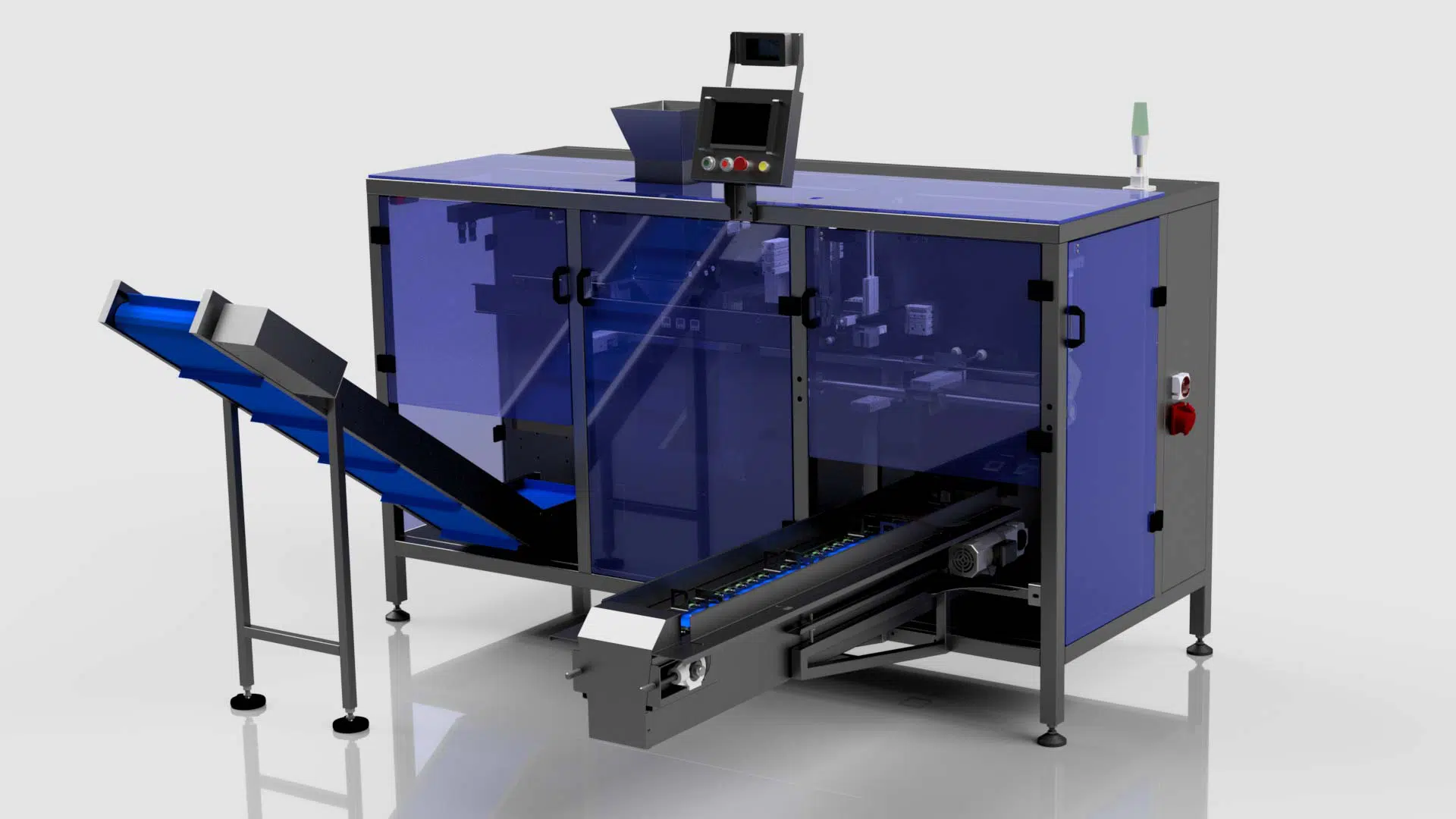

Precision Packaging with VFFS Technology: Explore Our Solutions

Streamlining Packaging with Versatility and Precision

Bessen Vertical Form Fill and Seal (VFFS) Machines: High-Speed, Reliable, and Accurate Packaging Solutions. Designed for ease of use, our VFFS machines offer versatility with various bag styles including pillow bags, gusset bags, 4-way seal bags, and flat bottom bags. Capable of working with laminated film and single-layer polyethylene film structures, Bessen provides complete, tailored packaging solutions for diverse industry needs.

Enhance your packaging process with Bessen's VFFS machines, equipped with additional options such as hole punch, tear notches, end-seal cooling, bag vibration, film tracking, vacuum film assist, bag support, map flashing, air expellers, and bag inflators.

Complementing our VFFS technology, we offer a range of filling equipment options including combination scales, linear scales, vibratory feeders, indexing conveyor systems, auger fillers, piston fillers, and cup fillers. Explore Bessen's innovative VFFS solutions and discover unparalleled packaging efficiency tailored to your business.

Premade Pouch Filling & Sealing Machines: Efficient, Versatile Packaging Solutions for Your Business

Bessen's Premier Premade Pouch Solutions: Streamlining Packaging with Innovation and Precision

Bessen's Premade Pouch Machines: Versatility and Efficiency at Every Level. From our small entry-level machine, capable of handling a wide variety of different bags, to our high-production, user-friendly models, Bessen offers the perfect solution for your packaging needs.

100-Series Pouch Machine: Our most compact offering, the 100-series machine is designed for precision and performance, capable of reaching speeds of up to 19 bags per minute.

500-Series Pouch Machine: For higher volume production, the 500-series machine is the ideal choice, designed for more substantial operations and achieving speeds of up to 33 bags per minute.

Explore Bessen's innovative range of premade pouch machines and discover how our state-of-the-art technology can elevate your packaging process. Quality, speed, and adaptability are at the core of Bessen's packaging solutions.

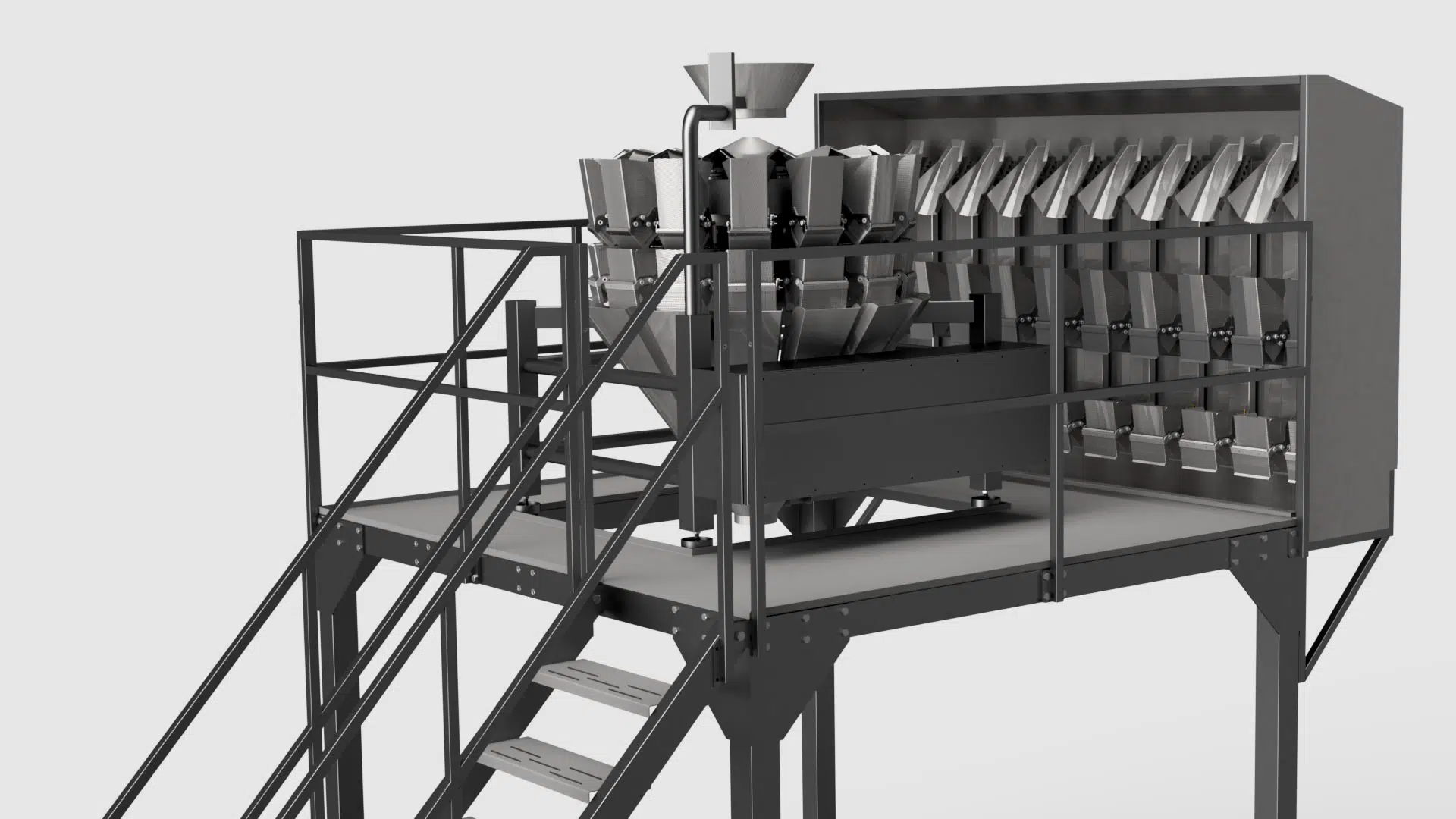

Bessen's V3 Series: Revolutionizing Weighing with Precision Combination Scale Technology

Advanced Multi-Head Weighing Solutions: Unmatched Accuracy and Speed for Your Packaging Needs

Bessen Combination Scales: Introducing the V3 Series for Precision Weighing and Mixing. Crafted with a full stainless-steel design, these scales are tailored to thrive in high humidity environments, featuring an active dehumidification option that monitors and controls humidity within the electrical cabinet. Available in both 10 and 14 head models, our V3 series mixing scales are versatile and adaptable to your specific needs. Capable of reaching impressive speeds of 150 bags per minute (BPM), Bessen's V3 series combination scales are the perfect solution for enhancing efficiency and accuracy in your weighing and mixing processes. Explore innovation and quality in every detail with Bessen's advanced weighing solutions.

BESSEN P1 & P2 Working Platform: Elevated Safety and Accessibility for Industrial Environments.

Integrating Sanitary Washing Systems: BESSEN's Working Platform for Hygienic Operations and Maintenance Efficiency

Bessen P1 & P2 Working Platforms: Tailored Solutions for Your Weighing and Conveying Needs. Designed to complement our V3-Series combination weigher and incline conveyor product feeding system, Bessen's working platforms embody our commitment to sanitary and efficient operations.

P1 Platforms: Featuring full stainless-steel construction and a stainless-steel diamond plate, the P1 platforms can be customized to the size, height, and position of the stairs, offering robust and adaptable solutions.

P2 Platforms with Washing Systems: Enhancing convenience and hygiene, our P2 working platforms can be equipped with washing systems. This innovation means that after a production day, the components from the combination weigher can be easily washed and sanitized on-site, without the need to carry them down the stairs.

Experience the blend of quality, flexibility, and hygiene with Bessen's P1 & P2 working platforms. Elevate your production process with systems thoughtfully engineered to meet your specific requirements.

Smart Wrap Bessen Flow Wrappers: Intelligent Packaging Solutions for Unmatched Efficiency and Precision

BESSEN Smart Wrap 250-600x Series: Next-Generation Flow Wrapping Technology for Versatile and High-Speed Packaging Solutions

Introducing Bessen Smart Wrapper 250-600X: Your Solution for Challenging Wrapping Needs. As a leader in packaging technology, Bessen presents the innovative SMART WRAPPER 250-600X series, inverted flow wrappers designed to handle the most delicate and challenging products.

Versatility in Design: Whether working with soft items or products that are difficult to propel, the 250-600X series offers an effective solution. These inverted flow wrappers feed plastic from the bottom, ensuring careful handling without compromising efficiency.

Customizable Options: Available in both painted steel and 304 stainless steel versions, these machines provide the durability and hygienic standards that modern industries demand. Choose between 2 VFD drives or 2 servo drive options to align with your specific needs.

Range of Sizes: Designed to cater to various production requirements, the 250-600X series comes in four different sizes: 250, 350, 450, and 600. This allows for flexibility in both manual and automatic loading configurations.

Explore Bessen's Smart Wrapper 250-600X series, and elevate your packaging process with technology that understands your product's unique demands. Experience the blend of precision, flexibility, and innovation that only Bessen can provide.

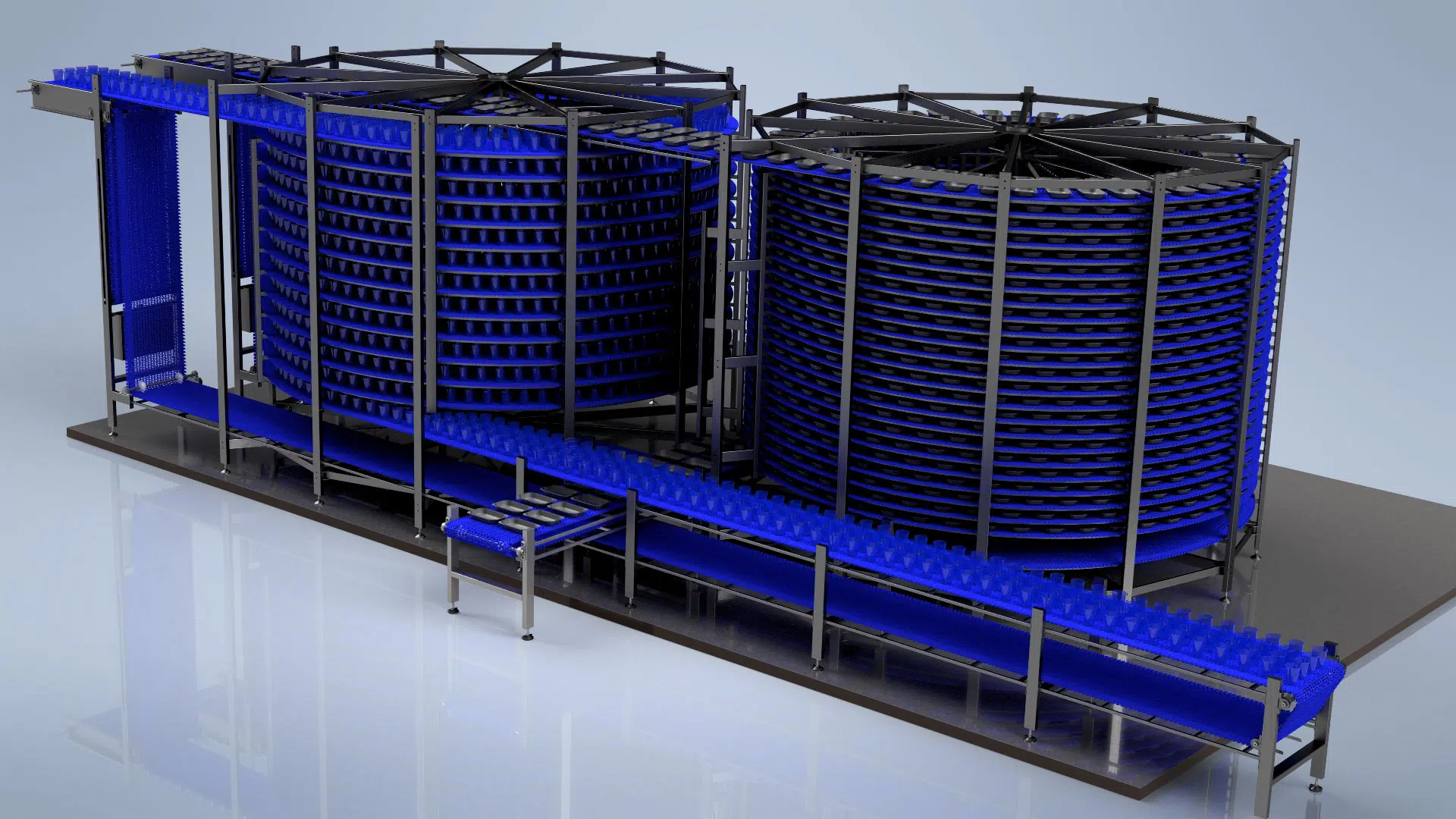

BESSEN Spiral Conveyor Systems: Innovative Vertical Transportation for Space Efficiency and Unmatched Reliability

BESSEN Spiral Chiller-Freezer Conveyor Systems: Seamless Integration for Temperature-Controlled Processing and Efficient Space Utilization

BESSEN's Spiral Chiller-Freezer Conveying Systems: Adaptable Solutions for Any Industry Requirement. Specializing in innovative conveying technology, BESSEN offers a wide array of spiral conveying systems designed to fit every need.

Versatile Options: From entry-level systems suitable for smaller product loads in constrained spaces, to industrial-sized conveyors capable of processing thousands of pounds per hour, ranging from fresh to frozen products, we have a solution tailored for your business.

Material Selection: Choose from different belting materials such as resilient stainless steel or modular plastic, ensuring durability and compliance with industry standards.

Innovative Design: Our low-tension spiral belt systems provide smooth operation, while our unique high-tension spiral types engage with a center drum and are directly driven by it as a giant sprocket, offering unmatched efficiency and precision.

Adapted to Your Needs: Whether your operation requires gentle handling of delicate items or robust performance for high-volume production, BESSEN's Spiral Chiller-Freezer Conveying Systems are crafted with the flexibility and reliability to exceed expectations.

Explore the BESSEN difference and enhance your production capabilities with our Spiral Chiller-Freezer Conveying Systems, a symbol of engineering excellence and innovation. Experience a new level of efficiency and control with BESSEN, a name synonymous with quality in the world of conveying technology.

Revolutionizing Safety and Quality Assurance: BESSEN Metal Detectors – M1 & M2 Series for Industry-Leading Performance

Integrity and Precision in Every Scan: BESSEN's M1 & M2 Series Metal Detectors for Unmatched Quality Control

Introducing BESSEN Metal Detectors: Ensuring Food Quality with Unmatched Accuracy and Flexibility.

Adaptability in Challenging Conditions: BESSEN's metal detectors excel in versatility, designed to operate even in the most demanding food processing environments, ensuring consistent quality control.

Customizable Conveying and Rejection Options: Tailor your detection system with different conveying options and rejection systems to align with your specific food processing needs, enhancing efficiency without compromising safety.

Horizontal and Vertical Detection Solutions:

Horizontal Metal Detectors: Ideal for packaged goods, BESSEN's horizontal detectors provide precise scanning, safeguarding the integrity of your packaged food products.

Vertical Metal Detectors: Designed for pre-packaged products, our vertical detectors offer meticulous control, ensuring that every food item meets the highest quality standards before packaging.

A Commitment to Food Safety: BESSEN's cutting-edge metal detectors are more than just machinery; they are a promise to your customers that every product leaving your facility has been thoroughly inspected and meets the highest standards of food safety.

Trusted by Food Producers Globally: BESSEN Metal Detectors are chosen by leading food manufacturers for their reliability, adaptability, and commitment to excellence.

Embrace the future of food quality control with BESSEN Metal Detectors. Invest in technology that understands the intricacies of food processing, providing solutions that are as diverse and unique as your products. Contact us to explore a world of detection possibilities tailored to the demands of the modern food industry.

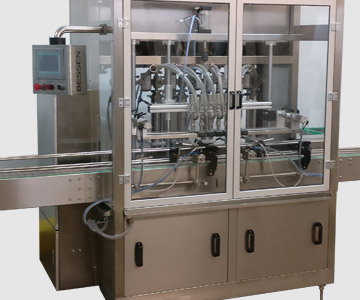

Unmatched Efficiency and Customization: BESSEN's Smart Fill Linear Filling Line – Tailored Solutions for Every Product

Precision and Adaptability at Your Fingertips: BESSEN's 4-12 Heads Filling Line for Exceptional Control and Versatility

Experience Unparalleled Accuracy with BESSEN's Smart Fill Linear Filling Lines – 4-12 Heads

Versatile Filling Solutions: BESSEN's Smart Fill Linear filling lines are tailored to handle various product viscosities, from thin liquids to thick viscous substances. Designed to accommodate different bottle sizes, these lines provide precise control, meeting customer specifications and adapting to a wide range of industry needs.

Two Distinct Filling Principles:

Pneumatic Driven Lines: A common choice for efficiency and dependability, our pneumatic driven lines represent robust solutions for diverse applications.

High-Accuracy Servo Drive Models: For the utmost precision, our servo drive models offer cutting-edge accuracy through volumetric pumps, ensuring every fill meets exacting standards.

Minimizing Foaming with Servo Models: The servo models excel in complex tasks, employing varying acceleration and deceleration pump speeds to minimize or completely eliminate foaming. This innovative feature allows seamless filling of even the most challenging products.

Programmable and Customizable: Our servo model operators can program and save specific details for each product, enabling a level of customization that ensures consistent, top-quality filling for every batch.

BESSEN's Commitment to Excellence: We provide a comprehensive range of filling lines and equipment, reflecting our commitment to quality, innovation, and customer satisfaction. Consult our sales specialists to explore the right filling solutions for your business.

Invest in BESSEN's bottle filling lines and take advantage of our industry-leading technology. With the precision of our servo models and the reliability of our pneumatic lines, we offer solutions that put you in control of every fill, enhancing productivity and quality.

Hours of Operation

MON – FRI

8:30am – 6:00pm

SAT

9:00pm – 3:30pm

SUN

We are closed

We are closed

Drop Us a Line

Don’t be shy. Let us know if you have any questions!