Combination Scale

Our combination scale providing high accuracy, speed and robust design.

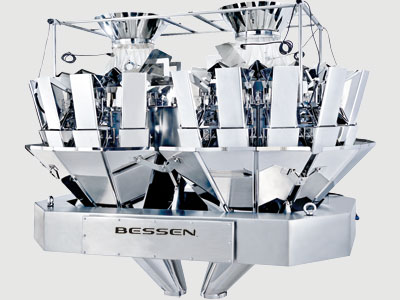

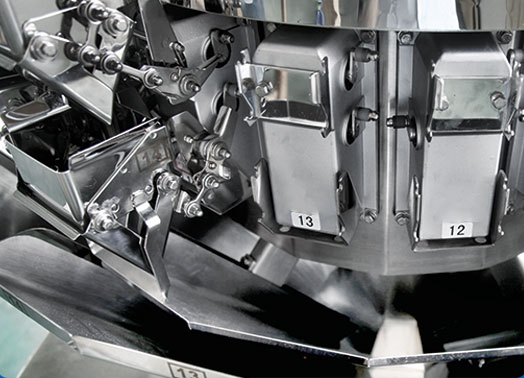

Smart Weigh 10-14 Versatile Smart Scale

SMART WEIGH 10-14

Smart Weigh 10-14 – High Speed Scale is the optimal scale for high speed packaging application. This scale is also optimal for weighing all different types of product. This scale can deliver high discharge speeds with high accuracy.

Smart Weigh 10-14 – Combination Scale.

This Combination scale was specially designed to work with products like chicken, pork, beef, duck, fish, as well as, other chunked meats and products. This system works very very well with cottage cheese and other slimier texture product.

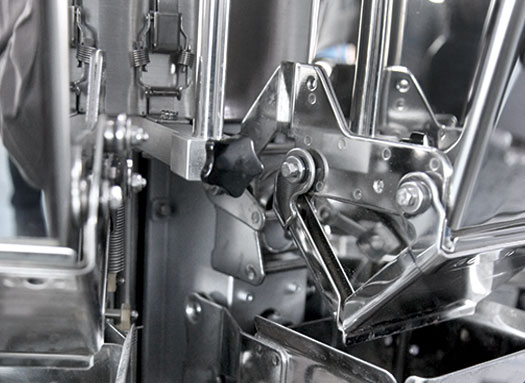

– High accuracy and high preseason load cells

– Intelligent multi sampling mote insures high accuracy and stability of the target weight.

– Intelligent Diagnosing and Alarm system will let you know about any maintenance that needed to be done to the machine.

– Intelligent self-diagnosing will alert you about any problems that machine might have. And what need to be done or replaced inside the machine.

– High speed stagger discharge will prevent product colliding and clogging packaging machine forming tube.

– High speed internal module communication and modular designee allows for machine to be hilly resistive to component failure.

– 9.7” HMI touch screen

– Traditional vibratory feeders are replaced with Screw feeders. This is more suitable for the large sticky and chunky products like meets and cottage cheese.

– IP 65 water resistant enclosure, Product contact surface made out of the dimple stainless steel, 60° discharge chute allows product to fall smoothly.

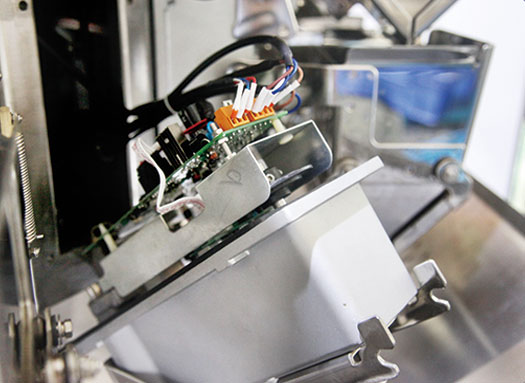

– Dehumidifying device is optimal allows to protect internal components from any humidity inside the machine.

– Pressurized frame is keeping moisture from getting inside the machine

– Heavy Stainless Steel frame are allowing stable operation and high accuracy at the higher operational speed.

Weighing Range – 10~1500G

Accuracy – 0.5G

Hopper – 2.5L

Max Speed – 50 P/M

Power – 208~240V 1phase 60Hz

HMI – 9.7” Touch Screen

Drive System – Stepper Motors

Gross Weight – 500KG

Smart Weigh 20-8 Smart Scale

Smart Weigh 20-8-O

Smart Weigh 16 – High Speed Scale is the optimal scale for high speed packaging application. This scale is also optimal for weighing all different types of product. This scale can deliver high discharge speeds with high accuracy

Smart Weigh 20-8-O – Combination Scale.

This Combination scale was specially designed to work with products like chicken, pork, beef, duck, fish or other chunked meats and products. This scale also works very well with cottage cheese and other slimier texture product.

– High accuracy and high preseason load cells

– Intelligent multi sampling mote insures high accuracy and stability of the target weight.

– Intelligent Diagnosing and Alarm system will let you know about any maintenance that needed to be done to the machine.

– Intelligent self-diagnosing will alert you about any problems that machine might have. And what need to be done or replaced inside the machine.

– High speed stagger discharge will prevent product colliding and clogging packaging machine forming tube.

– High speed internal module communication and modular designee allows for machine to be hilly resistive to component failure.

– 9.7” HMI touch screen

– Traditional vibratory feeders are replaced with Screw feeders. This is more suitable for the large sticky and chunky products like meets and cottage cheese.

– IP 65 water resistant enclosure, Product contact surface made out of the dimple stainless steel, 60° discharge chute allows product to fall smoothly.

– Dehumidifying device is optimal allows to protect internal components from any humidity inside the machine.

– Pressurized frame is keeping moisture from getting inside the machine

– Heavy Stainless Steel frame are allowing stable operation and high accuracy at the higher operational speed.

Weighing Range – 10~1500G

Accuracy – 0.5G

Hopper – 2.5L

Max Speed – 50 P/M

Power – 208~240V 1phase 60Hz

HMI – 9.7” Touch Screen

Drive System – Stepper Motors

Gross Weight – 500KG

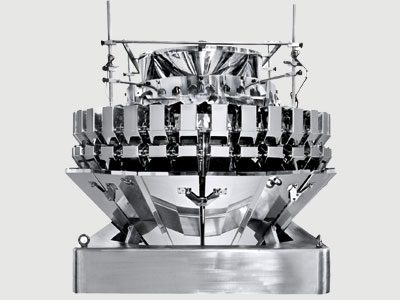

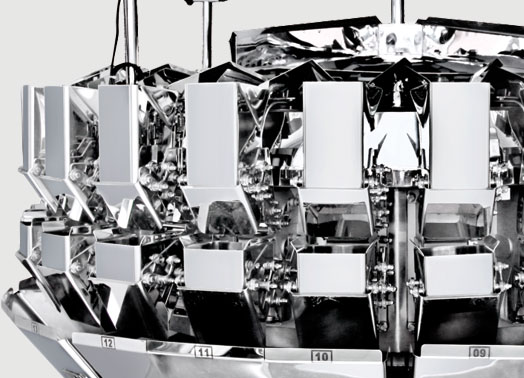

Smart Weigh 16 High Speed Scale

Smart Weigh 16 High Speed Scale

Smart Weigh 16 – High Speed Scale is the optimal scale for high speed packaging application. This scale is also optimal for weighing small granular product like seeds, coffee, tea, etc. This scale can deliver high discharge speeds with high accuracy.

Smart Weigh 16 – High Speed Scale.

This scale is designed to work with a small granular products such as seeds, coffee, tea, rice, corn, and other products. It can deliver the product at a high speed of up to 180 drops a minute.

– High accuracy and high preseason load cells

– Intelligent multi sampling mote insures high accuracy and stability of the target weight.

– Intelligent Diagnosing and Alarm system will let you know about any maintenance that needed to be done to the machine.

– Intelligent self-diagnosing will alert you about any problems that machine might have. And what need to be done or replaced inside the machine.

– High speed stagger discharge will prevent product colliding and clogging packaging machine forming tube.

– High speed internal module communication and modular designee allows for machine to be hilly resistive to component failure.

– 9.7” HMI touch screen

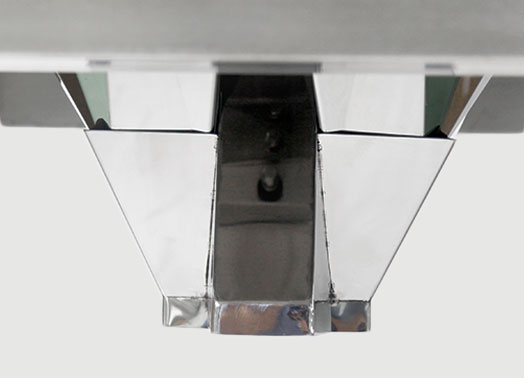

– Double chute to deliver in to 2 high speed timing hoppers

– Dehumidifying device is optimal allows to protect internal components from any humidity inside the machine.

– Pressurized frame is keeping moisture from getting inside the machine

– Heavy Stainless Steel frame are allowing stable operation and high accuracy at the higher operational speed.

Weighing Range – 10~200G

Accuracy – 0.5G

Hopper – 0.5L

Max Speed – 180 P/M

Power – 208~240V 1phase 60Hz 10A

HMI – 9.7” Touch Screen

Drive System – Stepper Motors

Gross Weight – 300KG

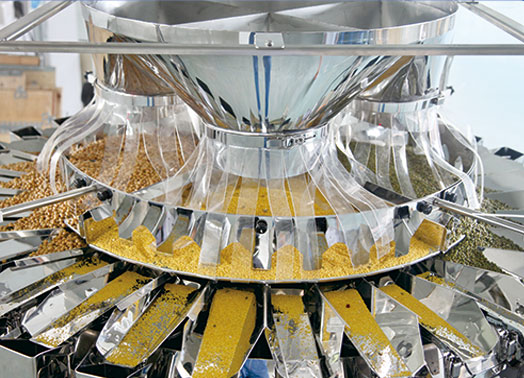

Smart Weigh 24 Head Mixing Scale

Smart Weigh 24 Head Mixing Scale

Smart Weigh 24 Head Mixing scale is designed to mix small granular products together into one package. It can mix 2 ingredients into 1 destination bag, 3 to 1, as well as, 4 to 1. High count of heads provide very high accuracy.

Smart Weigh 24 – Mixing Scale.

Application

– This scale is designed for small granular products such as, but not limited to seeds, tea, coffee, beans, corn, rice and more

– This scale is capable of high speed mixing operations for single or multiple discharge

– Can use for the mixing 2 in 1, 3 in 1 and 4 in 1 product

– 24 Hoppers to achieve high accuracy

– Mixing weight can be automatically compensated by a last product

– High accuracy and high preseason load cells

– Intelligent multi sampling mote insures high accuracy and stability.

– Intelligent Diagnosing and Alarm system will let you know about any maintenance that needed to be done to the machine.

– Intelligent self-diagnosing will alert you about any problems that machine might have. And what need to be done or replaced inside the machine.

– High speed stagger discharge will prevent product colliding and clogging packaging machine forming tube.

– High speed internal module communication and modular designee allows for machine to be hilly resistive to component failure.

– 10.4” HMI touch screen

– Upper Hopper funnel is divided in to weigh two different products at ones

– Separate main vibratory feeders to control feed of product independently

– Integrated control for higher accuracy and stability

– Dehumidifying device is optimal allows to protect internal components from any humidity inside the machine

– Pressurized frame is keeping moisture from getting inside the machine

– Heavy Stainless Steel frame are allowing stable operation and high accuracy at the higher operational speed

Weighing Range – 5~240G

Accuracy – 0.5G

Hopper – 0.5L

Max Speed – 60 P/M 4 mixing product

Power – 208~240V 1phase 60Hz 10A

HMI – 10.4” Touch Screen

Drive System – Stepper Motors

Gross Weight – 440KG

Smart Weigh 32 Head Mixing Scale

Smart Weigh 32 Head Mixing Scale

Smart Weigh 32 Head Mixing scale is designed to mix small granular products together in to one package. It can mix 2 ingredients into 1 destination bag, 3 to 1, as well as, 4 to 1. High count of heads provide very high accuracy.

Smart Weigh 32 – Mixing Scale.

Application

– This scale is designed for the small granular products such, as but not limited to seeds, tea, coffee, beans, corn, rice and more

– This scale is capable of high speed mixing operations for single and multiple discharges

– Can use for the mixing 2 in 1, 3 in 1 and 4 in 1 product

– 32 Hoppers to achieve high accuracy

– Mixing weight can be automatically compensated by a last product

– High accuracy and high preseason load cells

– Intelligent multi sampling mote insures high accuracy and stability.

– Intelligent Diagnosing and Alarm system will let you know about any maintenance that needed to be done to the machine.

– Intelligent self-diagnosing will alert you about any problems that machine might have. And what need to be done or replaced inside the machine.

– High speed stagger discharge will prevent product colliding and clogging packaging machine forming tube.

– High speed internal module communication and modular designee allows for machine to be hilly resistive to component failure.

– 9.7” HMI touch screen

– Upper Hopper funnel is divided in to weigh two different products at ones

– Separate main vibratory feeders to control feed of product independently

– Integrated control for higher accuracy and stability

– Dehumidifying device is optimal allows to protect internal components from any humidity inside the machine

– Pressurized frame is keeping moisture from getting inside the machine

– Heavy Stainless Steel frame are allowing stable operation and high accuracy at the higher operational speed

Weighing Range – 5~240G

Accuracy – 0.5G

Hopper – 0.5L

Max Speed – 60 P/M 4 mixing product

Power – 208~240V 1phase 60Hz 15A

HMI – 10.4” Touch Screen

Drive System – Stepper Motors

Gross Weight – 600KG

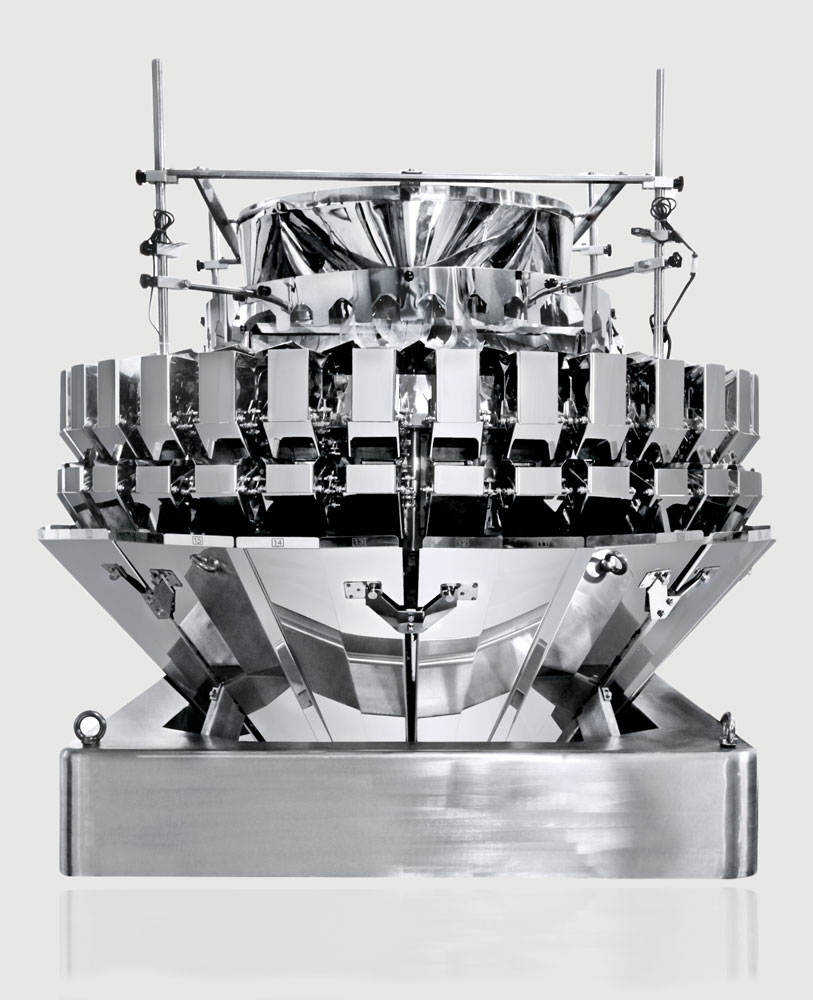

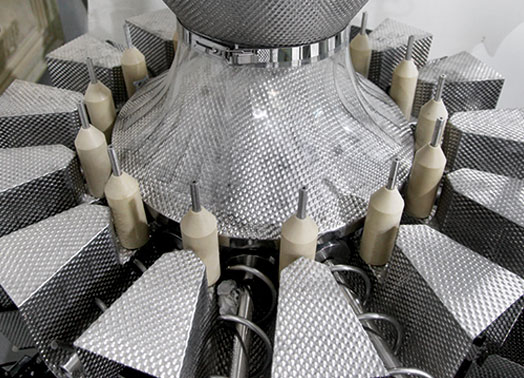

Smart Weigh 14 Head Meat Scale

Smart Weigh 14 Head Meat Scale

Smart Weigh 14 specially designed to work with a poultry meats, beef, pork, fish and other similar products, such as cottage cheese, as well as substances that are sticky and chunky to handle.

Smart Weigh 14 – Meat Combinations scale.

This combination scale was specially designed to work with products like chicken, pork, beef, duck, fish and other chunked meats and products. It works very well with cottage cheese and other similar texture product.

– High accuracy and high preseason load cells

– Intelligent multi sampling mote insures high accuracy and stability of the target weight.

– Intelligent Diagnosing and Alarm system will let you know about any maintenance that needed to be done to the machine.

– Intelligent self-diagnosing will alert you about any problems that machine might have. And what need to be done or replaced inside the machine.

– High speed stagger discharge will prevent product colliding and clogging packaging machine forming tube.

– High speed internal module communication and modular designee allows for machine to be hilly resistive to component failure.

– 9.7” HMI touch screen

– Traditional vibratory feeders are replaced with Screw feeders. This is more suitable for the large sticky and chunky products like meets and cottage cheese.

– IP 65 water resistant enclosure, Product contact surface made out of the dimple stainless steel, 60° discharge chute allows product to fall smoothly.

– Dehumidifying device is optimal allows to protect internal components from any humidity inside the machine.

– Pressurized frame is keeping moisture from getting inside the machine

– Heavy Stainless Steel frame are allowing stable operation and high accuracy at the higher operational speed.

Weighing Range – 10~1500G

Accuracy – 0.5G

Hopper – 2.5L

Max Speed – 50 P/M

Power – 208~240V 1phase 60Hz

HMI – 9.7” Touch Screen

Drive System – Stepper Motors

Gross Weight – 500KG

MON – FRI

08:30am – 6:00pm

Emergency calls

&

Contract Costumers

SUN

By appointmenr

Drop Us a Line

Don’t be shy. Let us know if you have any questions!